hardness test materials evaluation|example of hardness tester : distributing (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity . 5 de abr. de 2023 · Por Joanna de Assis e Yago Rudá — São Paulo. 05/04/2023 11h29 Atualizado há 10 meses. O Santos assinou nesta quarta-feira com mais dois reforços. O .

{plog:ftitle_list}

webOnlyFans. Do you agree with Carniello's 4-star rating? Check out what people have written so far, and share your own experience.

Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, . (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity .

The Mohs hardness test involves observing whether a materials surface is scratched by a substance of known or defined hardness. To give numerical values to this physical property, minerals are ranked along the Mohs scale, which is composed of 10 minerals that have been given arbitrary hardness values. For hardness evaluation ten standardized discs of each material were prepared and evaluated using vicker's hardness test. Results All the groups showed some amount of microleakage. The Monte Carlo simulation (MCS) method for uncertainty evaluation of measurement results has gained popularity as an alternative to the method based on law of propagation of uncertainty (LPU) ever since the recommendation by JCGM through supplement JCGM 101:2008. In this paper, efforts have been made to compute the uncertainty in .Anderson Materials Evaluation offers expert hardness testing services for a variety of materials. Our specialized tests use durometers, which measures the resistance of materials to indentation. This is crucial for understanding the durability and performance of materials in different applications.

types of hardness testing methods

principle of hardness tester

Leeb Hardness Testing – A Powerful Tool for Material Evaluation The Leeb Hardness Test has emerged as a powerful and versatile tool within the domain of material science testing. For those engineers seeking a cost-effective and efficient approach to evaluate the hardness and damage resistance of metallic materials, the Leeb Hardness Test .

Hardness of a material to deformation is dependent on its microdurability or small-scale shear modulus in any direction, . "Introduction to hardness testing." Mechanical testing and evaluation, ASM Online Vol. 8. External links. An introduction to materials hardness; Guidelines to hardness testing Archived 2021-02 .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

how to test for hardness

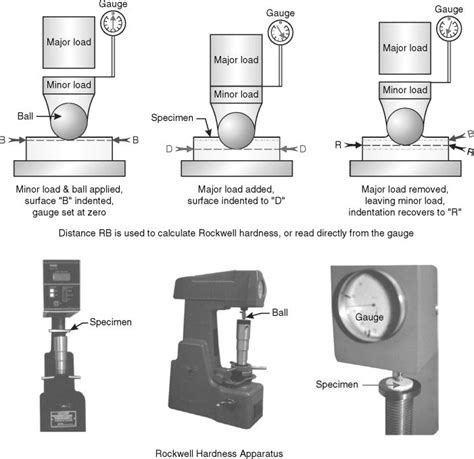

In the realm of material science and engineering,the assessment of hardness plays a crucial role in determining a material's suitability for specific applications.Among the various hardness testing methods,the Rockwell hardness test stands out as a widely used and versatile technique. Understanding Rockwell Hardness Te Provides an overview of the hardness testing of metals, plastics, rubber, and other materials based on current standards and practices. Covers technical developments such as the introduction of image processing in the Brinell and Vickers methods, the adaptation of hardness testing machines to process-oriented testing conditions, and the development of highly . Hardness Testing and Specimen Preparation Hardness testing is a useful tool for the evaluation of materials, quality control of manufacturing processes and in research and development work. It gives an indi-cation of a material’s properties, such as strength, ductility and wear resistance. 2.1 International Standards for the Evaluation of Rockwell Hardness Using a Microscope. Based on a comparison of international standards, identical measurement conditions and procedures were determined by the authors [].The international standards recommend nominal preliminary test force 29.42 N and nominal total test force 147.1 N.

how to measure surface hardness

E1842-96 Standard Test Method for Macro-Rockwell Hardness Testing of Metallic Materials (Withdrawn 2002) E110-14(2023) Standard Test Method for Rockwell and Brinell Hardness of Metallic Materials by Portable Hardness Testers . E1180-08(2021) Standard Practice for Preparing Sulfur Prints for Macrostructural Evaluation . E3-11(2017) Standard .Description of Technique. Durometer testing is used to determine the hardness of thermoplastic elastomers, vulcanized rubber, elastomeric materials, cellular materials, gel-like materials, and other plastics that are unsuitable for measurement by conventional Rockwell or microindentation hardness testing.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general characterizations 1.Material Characteristics • Test to check material • Test hardenability • Test to confirm process • Can be used to predict Tensile strength .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

Test Result Evaluation. Rockwell hardness values are determined by the penetration depth and are represented by a scale corresponding to the specific indenter and load used. The higher the number on the Rockwell scale, the . Materials and Methods: Two nano-hybrid composites i.e., Nexcomp by Meta Biomed, Korea, and Tetaric N Ceram by Ivoclar Vivadent, AG, Liechtenstein were selected, and hardness was evaluated . The interim restorative materials should have certain mechanical properties to withstand in oral cavity. The aim of this study was to evaluate the hardness and wear resistance of interim .

individual constituents of materials. Hardness Testing Theory Early methods generally consisted of scratching. Scratch hardness testing consists of penetration of the material surface by a testing point and bears a close resemblance to the indentation hardness test. One of the earliest forms of scratch testing goes back to Reaumur in 1722.Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .

how to do hardness testing

CAD/CAM (computer-aided design/computer-aided manufacturing) for indirect restorative materials has been recently introduced in dentistry. The purpose of this study was to evaluate the change of the surface micro-hardness of different restorative CAD/CAM materials after exposure to a carbonated acidic drink (Coca-Cola, Coca-Cola Company, Milan, Italy). .

Laboratory Turbidimeter factories

The dual-ion irradiation experimental test facility, DuET at Kyoto University was used for the self-ion irradiation experiment. The 5.1 MeV Cu 2+ ion beam was irradiated onto the surfaces of SC-Cu, MAed-Cu and ODS-Cu specimens simultaneously. Fig. 1 shows the depth profiles of the displacement damage and implanted Cu concentration calculated using SRIM .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method.

Hardness Testing: Equipment for reliable and accurate material hardness evaluation LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers, Brinell or Rockwell type testing.

Laser particle size Analyzer factories

The hardness of a material is the property that enables it to resist deformation, bending, scratching, abrasion, or cutting. If you work in materials manufacturing, you probably already know that a hardness test is a crucial step in the production process for your products and the products you receive from third-party suppliers. A micro-hardness test can be used to evaluate these mechanical properties. . Colombo M. Flexural Properties and Elastic Modulus of Different Esthetic Restorative Materials: Evaluation after Exposure to Acidic Drink. BioMed Res. Int. 2019; 2019:5109481. [PMC free article] [Google Scholar]

Kjeldahl Apparatus factories

Digital Automatic Polarimeter factories

WEB1 de abr. de 2022 · Anunciada temporada 2 de Shinka no Mi. Por Helder Archer. 1 , Abril , 2022. O twitter oficial da adaptação para série anime da novel Shinka no Mi: Shiranai Uchi ni Kachigumi Jinsei (The Fruit of Evolution: Before I Knew It, My Life Had It Made) de Miku e U35 revelou que estará a ser produzida uma segunda temporada intitulada Shin .

hardness test materials evaluation|example of hardness tester